Rigid PCB, commonly known as hard board, is a printed circuit board made of a rigid substrate that is not easily deformed. It has a stable structure, precise dimensions, and high line density, so it is widely used in fields with extremely high requirements for stability and reliability.

What is Rigid PCB? It is a printed circuit board made of solid substrate material, which has strong stability and can effectively prevent the circuit board from deforming. For example, our common computer motherboard is a multi-layer rigid PCB. It is like a huge electronic transportation hub, responsible for distributing power from the power supply, allowing various electronic components such as CPU, GPU, and RAM to communicate smoothly and complete various complex tasks together.

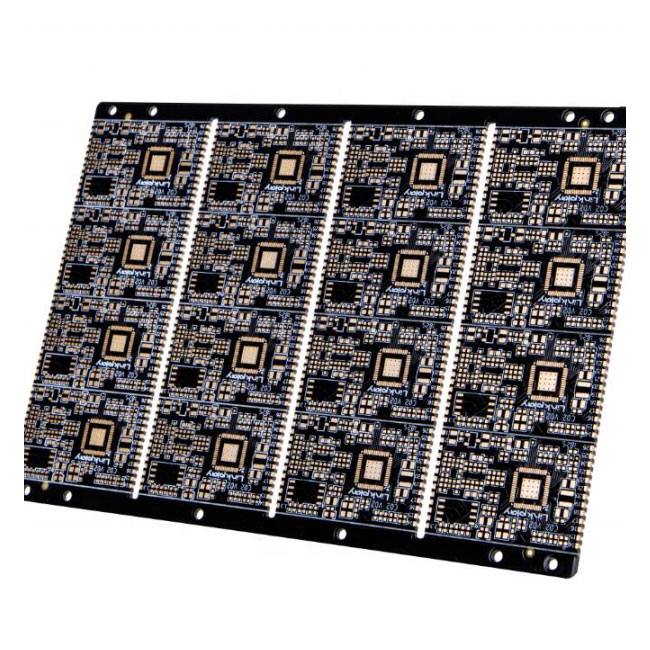

Rigid PCB is a traditional PCB that cannot be like a flexible PCB because the rigid PCB has FR4 reinforcement and cannot be twisted or folded into any shape, which is very useful for increasing rigidity. It consists of copper wires and paths, which are integrated on a board to connect different components on the board. The substrate of the board is made of a rigid substrate, which provides rigidity and strength to the board. Computer motherboard is the best example of a Rigid PCB with a rigid substrate material.

Rigid PCBs are cheaper than flexible PCBs. They are traditional PCBs that are widely used in many electronic products. They are used to connect multiple electronic components on a circuit board. How is it manufactured?

Rigid PCBs consist of different layers that are joined together using adhesives and heat, which provide a solid shape to the board material. Substrate Layer: The substrate layer, also known as the base material, is made of fiberglass. FR4 is mainly used as a substrate material, which is the most common fiberglass that provides rigidity and stiffness to the circuit board. Phenolic resin and epoxy resin are also used as substrates, but they are not as good as FR4. However, they are cheaper and have a unique bad smell. The decomposition temperature of phenolic resin is too low, which will cause the layers to delaminate if solder is left for a long time.

Copper layer On top of the substrate layer, copper foil is laminated on the board with the help of additional heat and adhesive. In daily use, both sides of the board are laminated with copper; however, some cheap electronic products have only one layer of copper material on the circuit board. Different board materials have different thicknesses, which are described in ounces per square foot.

The solder mask layer is placed on top of the copper layer. This layer is added on the board to add an insulating layer on the copper layer to avoid any damage when any conductive material comes into contact with the copper layer. The silkscreen layer is located above the solder mask layer. It is used to add characters or symbols on the board for a better understanding of the board. White is mainly used for silkscreen printing. However, other colors can also be used, including gray, red, black, and yellow.

Rigid PCB is an important part of core components such as computer motherboards, graphics cards, and sound cards, responsible for connecting and supporting various electronic components to achieve complex circuit functions. In portable communication devices such as mobile phones, GPS navigation, walkie-talkies, etc., Rigid PCB meets the needs of realizing complex electronic circuits in a small space with its high precision and high density. In addition, in large communication equipment such as base stations and satellite equipment, its high reliability and stability also make it the first choice.

In the field of industrial control, Rigid PCB is widely used in various controllers, sensors, instruments and other equipment to achieve precise control and data acquisition functions and ensure the stable operation of industrial systems. Medical equipment has extremely high requirements for data acquisition and control accuracy. Rigid PCB has become an important part of the electronic circuit of medical equipment with its high stability and reliability.

In today's era of rapid development of electronic technology, Rigid PCB, as a core component of electronic equipment, plays an irreplaceable role in different fields.