Rigid-flex boards combine the strengths of rigid printed circuit boards (PCBs) and flexible circuits into a single, integrated solution. As electronic devices become smaller, lighter, and more complex, rigid-flex boards have emerged as a critical technology enabling high reliability, compact design, and superior electrical performance. This in-depth guide explores what rigid-flex boards are, how they are manufactured, their advantages, applications, design considerations, and why companies like Akeson are trusted partners in delivering high-quality rigid-flex PCB solutions.

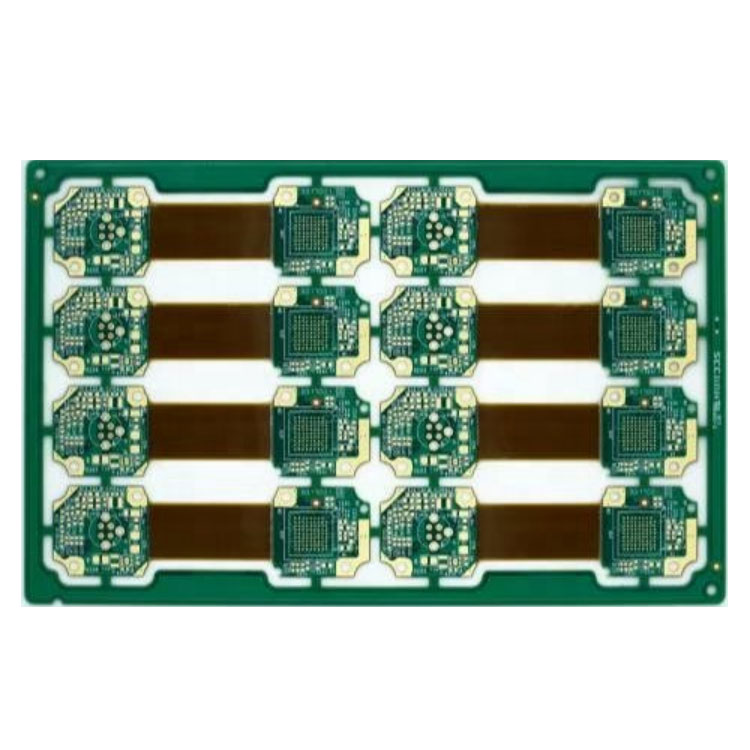

Rigid-flex boards are hybrid printed circuit boards that integrate both rigid PCB sections and flexible circuit sections into one unified structure. Unlike traditional designs that rely on connectors or cables to link rigid boards, rigid-flex boards eliminate these interconnects, resulting in a more compact, reliable, and lightweight solution.

By combining rigid and flexible substrates, rigid-flex boards allow designers to create three-dimensional circuit layouts that fit into tight spaces while maintaining excellent electrical integrity.

Rigid-flex boards consist of multiple layers of rigid and flexible materials laminated together. Each layer plays a specific role in ensuring mechanical strength, flexibility, and signal performance.

| Layer Type | Material | Function |

|---|---|---|

| Rigid Layer | FR-4 | Provides structural support and component mounting |

| Flexible Layer | Polyimide (PI) | Enables bending and folding |

| Copper Foil | Rolled or Electrodeposited Copper | Conductive pathways |

| Coverlay | Polyimide Film + Adhesive | Protects flexible circuits |

The manufacturing process of rigid-flex boards is more complex than standard PCBs, requiring advanced equipment and strict process control.

Experienced manufacturers like Akeson ensure that each step meets IPC standards to guarantee performance and durability.

Rigid-flex boards offer numerous benefits that make them ideal for advanced electronic systems.

| Feature | Rigid PCB | Flexible PCB | Rigid-Flex Board |

|---|---|---|---|

| Flexibility | None | High | Selective |

| Reliability | Medium | Medium | High |

| Assembly Complexity | High | Medium | Low |

| Cost Efficiency | Moderate | Moderate | High (System Level) |

Rigid-flex boards are widely used across industries that demand compactness and reliability.

Designing rigid-flex boards requires careful planning and collaboration with manufacturers.

Rigid-flex boards must meet strict quality requirements due to their use in mission-critical applications.

Akeson specializes in high-performance rigid-flex boards designed to meet demanding industry requirements. With advanced manufacturing capabilities, strict quality control, and deep engineering expertise, Akeson supports customers from prototyping to mass production.

While initial costs may be higher, rigid-flex boards often reduce overall system costs by minimizing assembly, connectors, and failures.

Yes. With proper impedance control and stack-up design, rigid-flex boards perform excellently in high-speed applications.

When designed and manufactured correctly, rigid-flex boards offer exceptional durability and long service life.

Industries requiring compact, lightweight, and reliable electronics—such as medical, aerospace, and automotive—benefit the most.

Rigid-flex boards are redefining how modern electronics are designed and built. By combining flexibility, strength, and reliability, they enable innovative products that meet today’s demanding performance requirements. If you are looking for a trusted partner to bring your rigid-flex PCB designs to life, Akeson is ready to help.

For customized rigid-flex board solutions, technical consultation, or project support, contact us today and discover how Akeson can power your next innovation.