Rigid-Flex Boards represent one of the most advanced PCB technologies in today’s electronics industry. By combining rigid and flexible circuit layers into a single integrated structure, rigid-flex PCBs deliver superior reliability, space efficiency, and electrical performance. This article explores what rigid-flex boards are, how they work, their benefits, applications, design considerations, and why manufacturers like Akeson are increasingly adopting this technology for high-end electronic solutions.

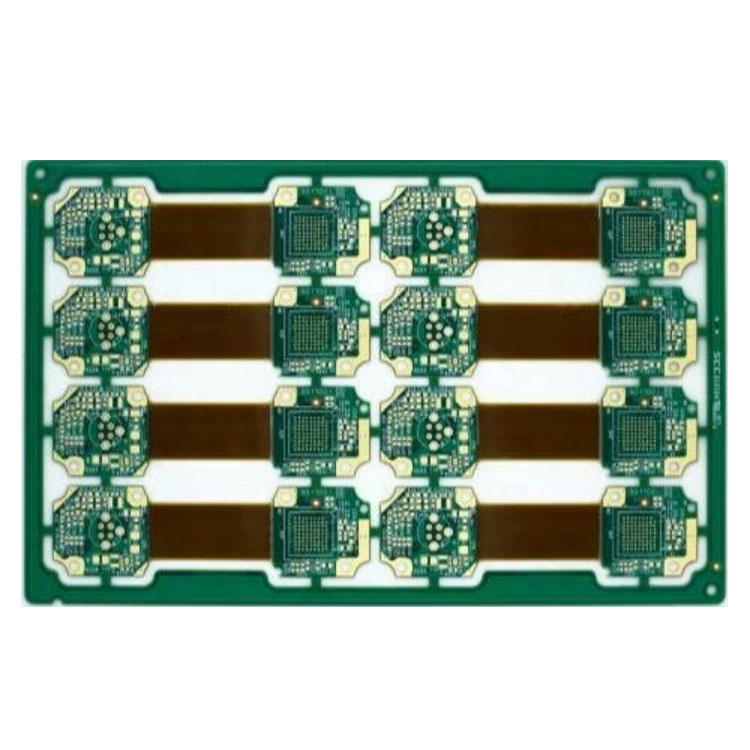

Rigid-Flex Boards are hybrid printed circuit boards that integrate both rigid PCB sections and flexible PCB sections into a single unified board. Unlike traditional designs that rely on connectors or cables to join rigid and flexible circuits, rigid-flex boards eliminate interconnects by embedding flexible layers directly between rigid sections.

This integrated approach significantly enhances electrical reliability, mechanical stability, and overall system performance. Rigid-flex boards are widely used in industries requiring compact, lightweight, and highly reliable electronic assemblies.

A rigid-flex PCB consists of multiple layers of rigid substrates and flexible polyimide layers laminated together. The flexible layers act as interconnections between rigid sections, allowing the board to bend, fold, or twist during installation and operation.

| Layer Type | Material | Function |

|---|---|---|

| Rigid Core | FR-4 | Component mounting and mechanical support |

| Flexible Core | Polyimide | Bending and dynamic interconnection |

| Copper Foil | Rolled Annealed Copper | Signal and power transmission |

Rigid-flex technology offers multiple advantages that make it a preferred solution for complex electronic designs:

| Feature | Rigid PCB | Flex PCB | Rigid-Flex PCB |

|---|---|---|---|

| Mechanical Stability | High | Low | High |

| Flexibility | None | High | Selective |

| Assembly Complexity | Medium | High | Low |

| Reliability | Medium | Medium | Very High |

Rigid-flex boards are widely adopted in high-reliability and high-density applications:

Manufacturing rigid-flex boards is significantly more complex than producing standard PCBs. The process involves precise lamination, controlled drilling, and advanced material handling.

Experienced manufacturers like Akeson leverage advanced production equipment and strict quality control systems to overcome these challenges.

Designing rigid-flex boards requires a different mindset compared to traditional PCB design:

While rigid-flex boards have higher initial manufacturing costs, they often reduce overall system costs by:

For mission-critical and high-density applications, rigid-flex boards provide exceptional value over the product lifecycle.

Akeson is a trusted PCB manufacturer specializing in advanced rigid-flex board solutions. With strong engineering expertise, reliable material sourcing, and rigorous quality assurance, Akeson supports customers from prototype to mass production.

Yes. By eliminating connectors and reducing solder joints, rigid-flex boards significantly improve reliability.

Yes, when properly designed with suitable materials and bend radius control.

Medical, aerospace, automotive, and high-end consumer electronics benefit the most.

Absolutely. They enable compact, three-dimensional packaging that minimizes space usage.

Rigid-Flex Boards are transforming the future of electronic design by enabling higher reliability, greater flexibility, and more compact systems. If you are looking for a professional partner to support your rigid-flex PCB projects, Akeson is ready to help. Contact us today to discuss your requirements and take your product design to the next level.