Summary: In the world of electronics, printed circuit boards (PCBs) are fundamental to connecting and supporting electronic components. 1-2 layer PCBs are widely used in various industries due to their cost-effectiveness and reliability. This article explores the benefits, applications, and considerations of using 1-2 layer PCBs in electronics manufacturing, focusing on how Akeson excels in providing high-quality solutions.

Printed Circuit Boards (PCBs) are the backbone of most modern electronic devices. A PCB allows the components of a circuit to be physically connected with one another while also providing electrical pathways. Among the various types of PCBs available, 1-2 layer PCBs are considered to be cost-effective yet versatile solutions for many applications. This blog will dive deep into what makes 1-2 layer PCBs so essential, the advantages they bring, and why Akeson is your trusted partner in this field.

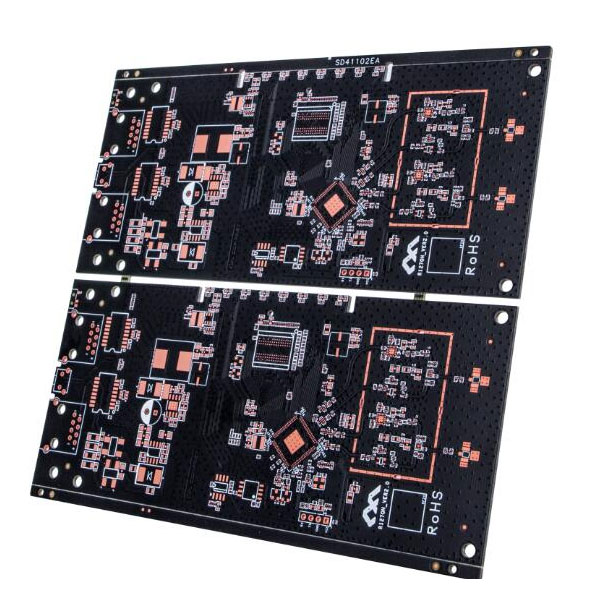

1-2 layers PCB refers to a type of printed circuit board that consists of one or two layers of conductive material (typically copper) that are etched to create electrical pathways. The more layers a PCB has, the more complex it is, but 1-2 layer boards are simpler and cheaper to produce.

1-layer PCBs have only one layer of copper, which is typically used for simpler designs. On the other hand, 2-layer PCBs have copper on both sides, allowing for more complex designs without increasing size. Both types are widely used for applications requiring simple or moderately complex circuits.

| Application | Benefits | Examples |

|---|---|---|

| Consumer Electronics | Affordable and reliable for everyday gadgets | Smartphones, Tablets |

| Automotive | Durable for electronic components in cars | Car audio systems, Control panels |

| Industrial Equipment | Cost-effective for machinery with simple circuits | Industrial sensors, Control systems |

| Medical Devices | Reliable performance for essential medical equipment | Portable health devices, Diagnostic machines |

The key difference is that 1-layer PCBs have a single layer of conductive copper, while 2-layer PCBs have copper on both sides. This allows 2-layer PCBs to handle more complex designs compared to 1-layer boards.

1-2 layer PCBs are not typically used for high-power applications as they have limited power handling capabilities. For high-power designs, multi-layer PCBs are more appropriate.

Yes, 1-2 layer PCBs are often used in automotive applications, especially for simpler electronic systems such as car audio or control panels.

If you're looking for reliable, cost-effective 1-2 layer PCBs, Akeson is here to provide top-quality solutions tailored to your needs. Contact us today to learn more about how we can support your next electronics project!